Tablet Coater

We manufacturer wide range of Tablet Coater , Auto Coater with film coating , Tablet Coating Machine , Tablet Auto Coater with sugar coating , Automatic Tablet Coating machine , Sugar Coating Pan machine, Conventional Coating machine, Pharma Tablet Auto Coater machine and equipment, Auto Coating Machine for tablet and pills ,Tablet Film Coating System , Coating Pan Machine , Confectionery Coating Pan machine, Chewing Gum Coating Machine ,Lab Auto Coater machine, Tablet Coater with film coating systems, Tablet Auto Coater, Pharmaceuticals Machines Manufacturer, Automatic Tablet Coating, Pharma Machinery Tablet Auto Coater, Auto Coating with Film & Sugar Coating system and equipments

We manufacture Automatic Tablet Coating System with film and sugar coating machine, this machine is complete PLC base automated system with controlled movement of the Pan, controlled inflow and out flow of air, controlled movement of solution for spraying, controlled spraying inshort everything is controlled by PLC so that uniform Coating is achieved. Tablet Coating System is available from 12 inches to 60 inches auto coater and coating pan machines with help of different futures and technologies.

Auto Coating machine for pallets, granules and tablets with various medium

- Film coating with organic solvent

- Film coating with aqueous coating

- Sugar coating

Tablet Coater , Auto Coater with film coating , Tablet Coating Machine , Tablet Auto Coater with sugar coating , Automatic Tablet Coating machine , Sugar Coating Pan machine, Conventional Coating machine, Pharma Tablet Auto Coater machine and equipment, Auto Coating Machine for tablet and pills ,Tablet Film Coating System , Coating Pan Machine , Confectionery Coating Pan machine, Chewing Gum Coating Machine ,Lab Auto Coater machine, Tablet Coater with film coating systems, Tablet Auto Coater, Pharmaceuticals Machines Manufacturer, Automatic Tablet Coating, Pharma Machinery Tablet Auto Coater, Auto Coating with Film & Sugar Coating system and equipments.

Technical Specifications of Auto tablet coating machine.

| Technical specification | ||||||

| Working Capacity-KG (Considering bulk density 0.97 gm/cc) | 10-20 | 40-70 | 60-100 | 80-150 | 200-350 | 350-500 |

| Pan Mouth Diameter -MM | 250 | 380 | 380 | 400 | 520 | 520 |

| Pan Speed - RPM | 5-15 | 2-10 | 2-10 | 2-10 | 2-10 | 2-8 |

| Main Drive FLP Motor - HP | 1 | 2 | 2 | 3 | 5 | 10 |

| Hot Air Inlet Blower - HP | 1 | 2 | 3 | 5 | 7.5 | 10 |

| Hot Air Fan Capacity - CFM | 350 | 1300 | 1600 | 2500 | 4000 | 5500 |

| Steam Consumption in (Kg/Hr) At Pressure (Bar) | 15-20 2-4 | 40-60 2-4 | 50-70 2-4 | 80-100 2-4 | 120-140 2-4 | 16-180 2-4 |

| Compressed air (CFM) At pressure 6 (Bar) q | 20 | 30 | 30 | 55 | 95 | 110 |

FEATURES

- compliance with cGMP guidelines

- Accurate batch consistency with high production efficiency & effective spraying with special design anti bearding type guns

- Quick accessibility for maintenance & cleaning

- Programmable Logic Controller

- Sugar Coating System (optional)

- nterchangeable Pans (optional)

- lameproof Construction (optional)

Tablet Coating Machine – Tablet Coating Pan, Pan Coating Machine, coating machine in pharmaceutical industry

- The tablet coating machine parameter complies with the Goods Manufacturing Practices (GMP) standard

- The machine’s components are quick and easy dismount without the overall use of tools for cleaning and maintenance

- The tablet coating machine construction is compact, allowing it to occupy a small space

- It contains an efficient air inlet and outlet handling system

- The machine can adjust the speed of the coating drum

- The PLC control is suitable as a data activity record is printable for evaluation

- The Pharmaceutical tablet coating machine is built by a type of material that is resistant to corrosion, ensuring continuous tablet coating machine operations and reduction of wear out costs

To succeed in today’s demanding pharmaceutical manufacturing environment, a tablet coating process must be as efficient as possible. This means that each step or aspect of the coating process must be optimized to suit the requirements of the specific product being coated, including how the tablets are fed into and discharged from the coater and how the coater is cleaned between batches or products. Optimizing each of these steps will minimize process time and ensure high-quality coated tablets despite variations in batch size or the depth of the tablet bed in the coating drum.

Tablet Feeding

The tablet feeding process transfers uncoated tablets from a storage container to the tablet coater drum. An optimized feeding process should be quick but gentle enough to prevent damage to the tablets. Pneumatic transfer processes should be avoided because they subject uncoated tablets to excessive mechanical stress and damage, making them a high risk to good manufacturing practice (GMP).

Manufacturers use many types of containers to supply uncoated tablets to coaters. Whichever type of feeding container you use, ensure that the container lifting unit and transition chute are customized to suit the coater’s feed opening. When planning a new coating line, consider the tablets’ angle of flow during feeding and the available height of the installation space. Uncoated tablets with poor flow characteristics may require a flow-aid mechanism to ensure complete tablet discharge from the feeding container. For tablets containing highly potent active ingredients, the coater feeding process is subject to a high risk of contamination. Such applications require containment valves and enclosed lines between the feeding container and coater to contain any dust generated during feeding.

The Coating Process

Once the tablets are loaded into the coating drum, the coating process can begin. Tablet coating consists of three sub-processes, or steps: mixing, spraying, and drying. During film coating, the coater executes each of these steps simultaneously; during sugar coating, there are usually separate cycles for adding the sugar solution, coating and mixing the tablet cores, and drying.

Mixing

Thorough mixing is a basic requirement for tablet coating. To ensure an even surface quality throughout the batch, the coater must expose all the tablets to the spray guns with a similar frequency so that they receive approximately the same amount of coating solution. To achieve this, coater manufacturers incorporate baffles on the inside of the drum that act as mixing elements. When developing a coater, the manufacturer carefully shapes these elements and adapts them to the drum geometry, so they create a gentle mixing action in the tablet bed as the drum rotates.

While older coaters were often equipped with large, sometimes height-adjustable, replaceable mixing elements, the mixing elements on modern coaters are significantly lower and fixed, as shown in Figure 1. These lower mixing elements provide a more uniform tablet-bed surface and prevent a wave-like, tumbling action in the tablet bed. The uniform tablet-bed surface prevents tablets from being sprayed at different distances from the spray nozzles, which can excessively moisten tablets at close distances or cause the spray droplets to dry in the air at greater distances.

Because the mixing elements are continuously covered by the tablet bed, they are not directly exposed to the coating spray. This prevents a partial film coating from sugar-coating processes, the mixing elements must not allow the highly sticky sugar-coated tablets any opportunity to get stuck in low- or no-flow recesses in the drum. Ramp-shaped mixing elements, as shown in Figure 2, are particularly suited to this process because they allow the sugar-coated tablets to glide over them, even if the tablets are very sticky.

Spraying

To apply coating solution or suspension to an entire batch of tablets as quickly as possible, it’s beneficial to maximize the number of spray nozzles and/or the tablet-bed surface area that’s exposed to the spray guns during coating. For this reason, drum coaters with an extended drum, a longer spray arm, and more spray nozzles, as shown in Figure 3, have become increasingly popular for film coating processes in recent years. The extended drum flattens out the tablet bed, exposing a greater percentage of tablets to the spray guns during operation.

Depending on the coating solution and the required droplet size, film coaters use either airless or two-substance spray nozzles. Airless nozzles, as shown in Figure 4, create an exceptionally homogeneous spray pattern at high pressure levels. As discussed earlier, it’s critical to maintain the correct distance between the spray nozzles and the tablet bed to prevent either over-moistening the tablets or the coating droplets drying before reaching the tablet bed. Maintaining the correct angle between the nozzles and the tablet bed surface is also critical. Many modern film coaters use auxiliary motors to precisely regulate the nozzle distance and angle automatically without requiring manual intervention by the operator.

Monitoring the spraying process with two-substance nozzles is usually limited to the spray-air pressure, the pattern-air pressure, and the coating solution spray rate. For particularly valuable or highly potent products, the coater may also monitor the liquid pressure in each coating solution line and trigger an alarm, automatic nozzle cleaning, or shutdown if it detects a malfunction such as clogging. Visual control systems with imaging technologies are not currently available but are being developed.

Drying

A modern coating process, as shown in Figure 5, uses optimized, high-volume spray rates that require suitable volumes of treated drying air. The air-line profiles and inlet openings on these systems are designed to keep the velocity of the drying air entering the coating drum low to minimize turbulence and pressure loss across the drum perforation and exhaust air system. Turbulent airflow in the coating drum causes some of the spray droplets to dry before contacting the tablet bed and be carried away in the exhaust airstream. This wastes coating solution and results in longer process times. It also affects tablet quality and limits the number of batches of the same product you can run without cleaning the coater.

The high drying capacity of modern coating systems makes it possible to coat even highly hygroscopic products, such as phytopharmaceuticals or plant extracts, with aqueous solutions. These systems can generate a lot of waste heat, however, so double-walled, insulated coaters that feature air-handling units equipped with heat recovery systems are in high demand. Such systems are not only more energy efficient, they are also safer because they maintain a temperature of less than 60°C on all metal surfaces. Moreover, because the systems mix cold and hot air in the air-supply system, they permit quick and precise temperature control.

Some products may require more complex machine lines with added components, such as a molecular sieve for air drying; a humidifying system or supply-air humidity control; or, for organic solvents, even a closed drying system that circulates inert nitrogen gas. Explosion-protected machine lines such as these can be very complex, particularly if multiple control circuits overlap and safety-related factors, such as a product with a very low minimum ignition energy, significantly affect the procedure.

Tablet Discharge

After coating, tablet discharge should be as quick as possible but gentle enough to prevent damage to the coated tablets. In recent years, helix-shaped welded discharge elements have replaced the special discharge inserts (called “scoops”) that were previously temporarily installed in the coater opening for the discharge process. These modified permanent elements serve as mixing elements when the drum rotates forward during coating but help to remove all tablets from the coating drum without any residue when the drum rotates backward.

For large production coaters, as shown in Figure 6, the number of discharge elements and their volume are selected so that a production batch of several hundred kilograms of tablets can be discharged completely in approximately 10 minutes without operator interference and while remaining gentle to the product.

For containment applications, the contamination risk decreases over the course of the coating process. A risk analysis should determine whether tablet discharge through containment flaps is required or whether no special discharge measures are necessary. In any case, process designers must take suitable measures to ensure that no product dust can emerge from the coater prior to, during, or after the entire coating and cleaning process.

Automated control system : The part controls the various functions automatically, for instance, operation of the machine, and the regulation of speed, pressure, and temperature.

Electric motors : They facilitate various tablet coating machine operations such as blowing air, mixing, and pressure creation , The touch screen operating panel facilitates observation, the input of controls, and monitoring by an operator with a user-friendly interface.

Guide plate: It allows for the smooth tumbling of the tablets when blowing hot air through them during the drying process, Peristaltic pump ensures constant pressure in the machine. During the spraying process, the pump aids in the stabilization of the atoms.

Spraying system: Components of this part are the nozzle, tank, and a pump, where it stores the tablet coating solution, ensures atomization stability, cleaning, and maintenance of the spraying pump. The Pan cooling surface consists of an automatic load cell system that helps in regulating the volume of the spraying solution. Its components include the electronic pulse valve, a discharging device, an exhaust dust collector, an air heating unit, and an air distribution device.

Coating preparation tank: The part facilitates the preparation of the coating solution

Spray rate: A low spray rate results in insufficient wetting, creating a brittle coat while a high spray rate over wets the tablets making them too sticky. Ensure the right spray rate before you begin the operations.

Air capacity: Air aids in drying the coated tablet, ensure sufficient air supply to prevent the occurrence of defects.

Coating composition: The operator must caution the proper mixing of materials to prevent defects such as a blockage, Rotation speed should not exceed optimum levels, and to achieve proper equipment efficiency, ensure all other components are operating at optimum levels under appropriate regulation of the processes.

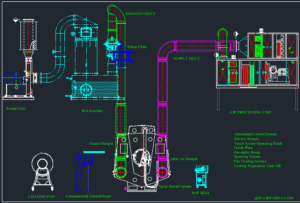

TABLET COATING SYSTEM consists of main perforated pan coating chamber in process area along with solution tank , spraying pump and a flameproof operating panel. Air Handling unit for suction and exhaust are mounted in service area along with dust collector or wet scrubber.

TABLETS COATED

- The core contains a substance which imparts a bitter taste in mouth or has unpleasant odour.

- To modify drug release profile e.g. sustained release, enteric coating, osmotic pumps etc

- The core is pharmaceutically inelegant

- Core contains a substance which is unstable in the presence of light and subject to atmospheric oxidation

- The active substance is colored and migrates easily to stain patients hands and clothes

- Separates incompatible substances by using the coat to contain one of them General Description

- Automatic Tablet Coating Machine is a result of our comprehensive understanding of the needs of our customers in the Pharmaceutical Industry, Food & other Industries, especially their ability to respond quickly to the demands of their markets and more importantly to produce high quality products, consistently.

-

Customers require their coating systems to be able to produce coated products within high quality standards and at the same time with high efficiency in terms of material usage and energy consumption.

-

That is why we are constantly innovating & enhancing our Automatic Tablet Coating Machine range of coating systems. All equipments are designed & manufactured keeping GMP as an integral specification.

-

Automatic Tablet Coating Machine is high efficiency/clean design/improved control

-

It is high efficiency, energy saving, safe and clean equipment for film coating and sugar coating of tablets, pills, pellets and candies with aqueous, non-aqueous, non-enteric film coating and sugar coating.

Process:

-

The tablet to be coated make continuous complex orbital motion the close rotating drum under the action of modernize of baffles. During the motion coating medium automatically sprays according to the technological process and logical technological parameters.

-

At the same time hot filtered air supplied under the negative pressure.

-

The hot air penetrates through the tablets core layers and is discharged from the bottom of the layers, so that the coating medium sprayed on the surface of the tablet cores will dry quickly and consistently, thus forming a solid and smooth surface film on tablet.

-

The entire process is completed under the automatically by PLC controls with colour touch screen HMI interface

Optional Features:

-

CIP/WIP Systems

-

Pan Interchangeability (with trolley and parking racks up to 60”)

-

Steam & electric heat exchanger

-

Tablet charging by bin loader

-

Sugar Coating System

-

Exhaust Air Treatment System

-

Mass Flow Meter Based Spray Rate Control Systems

Features:

-

Inlet Air Handling Units (AHU)

-

Our range of high-quality air handling systems are an integral part of our Automatic Tablet Coating Machine. The control of temperature & humidity within the Automatic Tablet Coating Machine is critical to the performance of the machine and wie make sure that each AHU is designed for the application. Each unit is designed to meet the customer’s needs and these air handling systems can be configured to meet the most demanding environmental conditions.

-

Modular design to meet process requirements and space limitations

-

Dehumidification of inlet air using chilled water, brine or desiccant systems

-

Mist removal system is provided

-

Air heating system with a choice of energy sources such as steam or electrical energy

-

Filtration to the highest standards

-

Anti-Bearding Spray Nozzles

With the new Anti-Bearding Nozzles, an excellent spray pattern is achieved without any beard formation. For the first time the distance between the bed & the spray nozzle is displayed on the HMI screen. The spray angle and distance are adjustable. The nozzles are easy to clean. -

Changeable Pan System

Now, you can exchange a pan in the equipment. This gives batch size flexibility in the same equipment. Investment is only required for a single piece of equipment. This feature is modular and can be supplied as an option. -

Single Tablet Discharge

The discharging system is designed & engineered to discharge a single tablet from the pan without manual intervention. The discharge system can be installed without any tools & is easy to remove from the pan after discharge. -

Robust & Reliable Process Control

With a high-tech PLC – HMI system is the heart of the equipment control center, all the process parameters are within very accurate control as well as accessible for operator to monitor as well as record. Exhaustive controls are provided for utilities as well.

Technical Specifications

| MODEL | SBAC – 24 | SBAC – 36 | SBAC – 48 | SBAC – 60 | SBAC – 66 |

|---|---|---|---|---|---|

| Pan Diameter – Inch (mm) | 24 (600) | 36 (920) | 48 (1220) | 60 (1525) | 66 (1675) |

| Brim Volume (Liter) | 25 | 105 | 212 | 630 | 1000 |

| Working Capacity – (Kg) | 5 to 20* | 20 to 55* | 70 to 150* | 120 to 300* | 180 to 400* |

| Pan mouth diameter (mm) | 250 | 380 | 400 | 520 | 520 |

| Pan Speed (RPM) | 2 to 15 | 1 to 24 | 1 to 16 | 1 to 10 | 1 to 10 |

| Main Motor (Hp) | 1 | 2 | 3 | 5 | 7.5 |

| Inlet Blower Motor (Hp) | 1.5 | 1.5 | 5 | 10 | 10 |

| Inlet Air CFM | 750 CMH @200 WC | 1400 CMH @200 WC | 3000 CMH @200 WC | 6000 CMH @200 WC | 2000 m3/Hr @200 WC |

| Exhaust Blower Motor (Hp) | 7.5 | 10 | 20 | 40 | 20 |

| Air Flow Outlet CFM | 750 CMH @900 WC | 1400 CMH @900 WC | 3000 CMH @900 WC | 6000 CMH @900 WC | 2500 @900 WC |

| Spraying Nozzle | 1 | 2 | 3 | 4 | 4 |

| Spray Rate (gm/minute) | – | – | 50 to 130 | 50 to 130 | 50 to 130 |

| Peristaltic Pump Motor (Hp) | 0.25 | 1.0 | 1.0 | 1.0 | 1.0 |

| Peristaltic Pump Speed (RPM) | 1 to 99 | 1 to 99 | 1 to 100 | 1 to 100 | 1 to 100 |

| Solution Preparation tank (Liter) | 25 (0.25hp) | 50 (1 hp) | 100 (1 hp) | 150 (1.5hp) | 150 (1.5hp) |

| CIP Pump Motor (Hp) | 1 | 1 | 2 | 2 | 2 |

| Steam consumption Kg/Hour @4 bar | 32 | 70 | 150 | 350 | 292 |

| Compressed air CFM @6 bar | 10 | 10 | 60 | 90 | 110 |

| Wet Scrubber Pump Motor (Hp/RPM) | 1 / 2880 | 2 / 2880 | 2 / 2880 | 2 / 2880 | 2 / 2880 |

| Automizing Purging Air (CFM) | 20 | 40 | – | – | – |

| Automizing Purging Air Pressure (Kg/Cm2) | 2.0 to 6.0 | 2.0 to 6.0 | 2.0 to 6.0 | 2.0 to 6.0 | -2.0 to 6.0 |

| Chilled Water @3 bar Pr. & 5°CHW Inlet temperature | 10 USGPM | 12 USGPM | 50 USGPM | 85 USGPM | 85 USGPM |

Equipment parameters are indicative and subject to change as per requirements. Units in mm and shown as a reference only

* Depending upon the characteristic of material and shape & size of tablets. | Due to continuous development in design and improvement, the Specifications described in this offer are subject to modification change without prior notice.

Coating Machine

- The tablet coater must maintain negative differential pressure to the coating suite with the sample port, service door, or main front door open.

- Hot inlet air should be supplied to the coating pan through the supply duct and should move inside the coating pan. The air inside of the coating pan should move through the tablet bed and then air should exhaust to the dust collector through an exhaust duct.

Spray gun:

- Spray guns provide efficient and uniform coating, along with smoother operation

- The coating machine should be supplied with anti-bearding Schlick guns with high volume at low-pressure type.

- The spray nozzle size should be 1.0mm.Coating Machine

- Depending on the depth of the coating pan fixed on the coating machine, the number of guns should be increased or decreased.

- The atomizing air pressure for each gun should be monitored with the help of a human-readable and or digital measuring device and can be adjusted from the regulator and or HMI.

- Provision shall be provided for easy adjustment of spray gun angle with respect to the coating bed as well as adjustment of the distance between the coating bed and spray.

- There should be minimum exposure of solution tubes and pneumatic tubes of spray guns within the coating pan.

- If the machine (coating pan) stops suddenly or due to any alarm, the spray gun will also stop functioning to avoid any drop of solution to the tablet’s bed.

Damper:

- The machine will be supplied with Auto Damper for the inlet and an outlet with a bypass flap for hot air.

- Steam-based heating with PID-controlled face/bypass system to ensure accurate air temperature control

- Temperature measurement to measure and control the for-inlet air temperature.

- The actuator positions should be programmable based on the coating cycle (film coating or sugar coating).

Pump & it’s manifold:

- The mostly multi-head peristaltic pump distributes spray liquid evenly to each nozzle through a spray manifold inbuilt into the spray arm. Supplied mounted on the machine frame.

- Pumping system Integrated with control system

- Pressure transmitter to detect gun choking

- A rotary pump will be used for Sugar coating. The pump transports the spray liquid to the in-feed rake because in case of the sugar-coating solution is viscous.

- Frequency converter for the speed adjustment of the spray pump

- The Film coating pump with Adjustable RPM speed and The RPM of the pump can both be controlled from the HMI or the pump itself.

The calculation for the Capacity tablet coating machine:

The capacity of a tablet coating machine in the pharmaceutical industry can be calculated using the following formula:

Capacity = (Tablet weight x Batch size x Coating time) / Coating efficiency

Here are the steps to calculate the capacity:

- Determine the weight of each tablet. This can be obtained by weighing a sample of tablets and dividing the total weight by the number of tablets.

- Determine the batch size, which is the total number of tablets to be coated in a single batch.

- Determine the coating time, which is the total time required for coating a batch of tablets. This includes the time for loading and unloading the tablets, as well as the actual coating time.

- Determine the coating efficiency, which is the percentage of coating material that actually adheres to the tablets. This can be determined through trial runs and adjusting the machine settings accordingly.

- Plug in the values into the formula:

-

-

Capacity = (Tablet weight x Batch size x Coating time) / Coating efficiency

-

-

By following these steps and using the formula, you can calculate the capacity of a tablet coating machine in the pharmaceutical industry.

Critical Parameters of a tablet coating machine

The critical parameters of a tablet coating machine in the pharmaceutical industry are:

- Inlet Air Temperature: The inlet air temperature is a critical parameter as it affects the drying time and the quality of the coating. The temperature needs to be controlled to ensure the tablets are not overheated, which can cause degradation or melting of the coating.

- Spray Rate: The spray rate is the amount of coating solution that is sprayed onto the tablets per unit of time. It is critical to ensure that the spray rate is consistent throughout the coating process to achieve a uniform coating thickness.

- Atomization Pressure: The atomization pressure is the pressure at which the coating solution is sprayed onto the tablets. It is essential to maintain the correct atomization pressure to ensure proper droplet size and distribution, which affects the quality and uniformity of the coating.

- Pan Speed: The pan speed is the speed at which the tablet bed rotates in the coating pan. The pan speed needs to be carefully controlled to ensure that the tablets are evenly coated and that there is no over-coating or under-coating.

- Coating Solution Viscosity: The coating solution viscosity is a critical parameter as it affects the spray rate, atomization, and drying time. A high viscosity can result in uneven coating, while a low viscosity can cause the coating to be too thin and easily damaged.

- Exhaust Rate: The exhaust rate is the rate at which the air is removed from the coating chamber. It is critical to maintain the correct exhaust rate to ensure that the tablets are properly dried and to prevent the buildup of solvents or coating material in the coating chamber.

- Coating Solution pH: The pH of the coating solution is important as it affects the stability and solubility of the coating material. A pH outside the recommended range can result in a poor-quality coating or even damage to the tablets.

By closely monitoring and controlling these critical parameters, a pharmaceutical manufacturer can ensure that their tablet coating machine is producing tablets with a high-quality, uniform coating that meets the required specifications.

Air Processing unit (APU) with Heat exchanger:

- The APU should supply filtered and hot air to the coating pan through the supply duct.

- Double-walled inlet air unit with dehumidification and heating system. Automatically controlled inlet air temperature, airflow speed, and dehumidification chamber temperature through PID. Humidity measurement at the inlet of the machine.

- Internal wall MOC – SS304

- External wall MOC – Galvanized Iron, powder coated

- Filter frames – Aluminum

- Provided with limit switches on all doors, interlocked with control system

- Provided with HEPA validation ports

Air Processing Unit

Filter Set EU4/EU7/EU13

Pre-Filter

- Pre-filter Grade EU4

- 85-90% down to 3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

Fine Filter

- Fine filter Grade EU7

- 85% down to 0.3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

HEPA Filter

- HEPA filter Grade EU13

- 997% down to 0.3 microns

- Equipped with a Magnehelic gauge for local differential pressure indication

Equipped with a differential pressure transmitter for indication on HMI.

APU consists of a heating coil to heat the filtered air. The steam valves should automatically be controlled with the help of the software PID controller working in concordance with the PLC commands and the user input temperature set on the HMI of the machine.

The present temperature of Inlet air shall be displayed on the variation in actual and the set temperature should not be more than + 3.0 °C. Temperatures (with PT100): +/- 1 % of the measuring range

The machine has auto spray cutoff provision interlock with inlet temperature (when inlet temperature breaches the upper and lower temperature set point for inlet air).

The maximum set value for inlet temperature will be 90°C (higher than this is acceptable).

Dust collector:

- Dust collector for exhaust and discharge the air from the coating pan through the exhaust duct.

- Active exhaust air deduster unit with H10 filter. Equipped with a removable dust collecting container with quick release for the dust of filter stage. Automatically controlled air purging integrated with a differential pressure switch. Additional passive H13 filter.

- The dust collector has cartridge filters through which the exhaust air should pass.

- These filters should trap the waste powders and suspend them onto the tray at the bottom of the dust collector.

- Dust collector has the function of exhausting and discharging the air from the coating machine. By going through the dust collector, air with the dirt is cleaned by the cartridge filter. The temperature of the exhausted air should be checked by the sensor and displayed in HMI

- The dust collector should consist fan and the speed of the fan is controlled by the inverter

Wet Scrubber:

A wet scrubber is used by transferring solid particles from a gas stream to a liquid, wet scrubber procedures remove them from the stream. The energy required to touch the gas stream with the scrubber liquid determines how effectively a wet scrubber collects particles.

CIP System:

- The machine shall be supplied with a CIP system (Clean In Place System) that

- The CIP system should supply high-pressure water the to CIP points located in the coating pan.

- The clean-In-Place system consists of strategically placed washing nozzles to ensure hassle-free cleaning validation in a low-downtime environment.

- Machine constructed to minimize crevices and difficult-to-reach areas

- WIP Skid consists of a Media supply with connections for o Warm water

- Cold water

- Purified water

- Compressed air

- These connections are equipped with check valves to prevent back-flow

- Flow switchCoating Machine

- Booster Pump

- Distribution valves

- Control System

- CIP system ensures complete cleaning of a coating pan, spray guns, supply, and exhaust ducts, and ensures complete drains of water used for cleaning from the machine.

- All wash water contact parts must be compatible with pharmaceutical-grade detergents with a range of 1.5 to 13.7 pH.

Control System:

The machine has a fully automated control panel

- The machine has both supply temperature controller mode and exhaust temperature controller mode.

- The machine has displayed DPIP (Differential pressure inside the pan) and DPIE Differential pressure inside the exhaust.

- The machine has displayed supply velocity (In CFM) and Humidity (in obsolete term g/kg).

- A pressure gauge shall be provided for measuring Differential pressure across the HEPA filter.

- The auto-coating should be recipe controlled.

- The CIP cycle should be recipe controlled.

- The operator should not be able to modify or delete the parameters of the stored recipe.

The recipe should have set points for the following (Not limited to):

- ►Exhaust Temperature set

- ►Exhaust Fan Speed

- ► Supply Temperature

- ► Supply Fan Speed

- ► Spray Atomizing Air pressure

- ► Coater Differential Pressure

- ► Coater Pan Speed

- ► Solution Pump Speed

- ►Machine should have audiovisual alarms.

- ►Machine should have alarms for the following:

- ► Main air shortage

- ► Trip coater motor

- ► Trip exhaust fan motor

- ► Trip supply fan motor

- ► Completed Film coating/sugar coating

- ► Exhaust temp over limit/exhaust temp low limit

- ► Glass open

- ► Buzzer Off/On Select

- ► Product temp over / low limit

- ► Supply temp over / low limit

- ► Solution tank temp over / low limit

- ► D.P.I.P High/low

- ► D.P.I.E High/low

- ► Communication failure 21CFR Part 11 requirements (There are bare minimum requirements)

Function

- Film Coating:Spray one thin protection layer on the surface of tablet (used in aqueous or organic solvent).

- Enteric Coating:Spray one protection layer on the surface of tablet to against stomach acid.

- Sugar Coating:Multi-layers of sugar coated to protect the tablet.

Theory

Hot airflow pass through a special designed film, heat the uniform rolling tablets inside, spray solution downward on the rolling tablet through pump and spray gun to get coating and drying purpose.

Application

- Pharmaceutical:

- Western medicine:film coating, enteric coating, sugar coating, control released coating.

- Chinese medicine:film coating.

- Food:

- Film coating:agriculture products, crystal sugar health food.

- Sugar coating:chewing gun, yeast candy, health food.

- Seed:Protection layer coating or add nutrition.

Feature

- Film and sugar coating are in one machine.

- Punched hole pan design for efficient drying.

- Short operation time:

- Film coating:1 ~ 3 hr/batch.

- Enteric coating:3 ~ 4 hr/batch.

- Sugar coating:6 ~ 16 hr/batch.

- Explosion proof system is available for organic solvent process.

- Auto discharge system for easy discharge.

- Auto control design for sugar coating, even no experienced operator can easy operate also. Well mixed sugar syrup, automatic fixed amount and fixed time, easy operation.

- Uniform coloring, weight and smooth surface for sugar coating.

- Operation time about 6 ~ 16 hr/batch of sugar coating.

General Description:

- Designed to confirm cGMP norms

- S.S. 304 Outer Chamber reinforced with Structural Steel

- Low Vibration Design

- Radial Corner for easy cleaning

- Easy to clean and maintain

- Completely enclosed design with leak proof doors

Optional features:

- Imported Spray Nozzle (Spraying Systems –USA ; Shlick-Germany)

- Imported Peristaltic Pump (Watson Marlow)

- Options of Recipe Handling

- Option of CFR Part 11 compliance

- Flameproof panel in process area