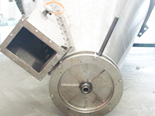

Screw Mixer, Vertical Ribbon Mixer

We offer best powder mixer including Screw Mixer , Vertical Ribbon Mixer , Nauta Mixer For Dry Powder , Conical Ribbon Mixer with many assembly in mixer like transmission device, outer ribbon mixer, taper cylinder , inner reverse screw mixer and discharge valve. Powder mixer machine / Conical Screw Blender new design for viscosity materials. The material circles and rises under the operation of the outer ribbon mixer, while the inner reverse screw presses down the material along the shaft, which finishes the mixing. With a long force arm and weak impact force,this equipment is suitable for the mixing and reaction of highly adhesive liquids with viscosity under 200, 000cp, such as paint, coating material and adhesive. It is particularly useful for the mixing of non-Newton fluids containing a lot of solid elements.

- Volume: 100-5000L

- Stainless Steel or Carbon Steel

- Ribbon & Screw agitator for bottom discharge

- Designed for normal temperature and normal atmospheric pressure

- Feed Nozzle

- Dust Nozzle

- Manually operated or Pneumatic operated dislocated valve

- Packing Seal

- Safety limit switch on man hole

Optional Features:

- Stainless Steel 304, Stainless Steel 316L

- Internal pressure

- Sanitary type construction

- Dislocated valve, butterfly valve, slide gate valve, ball valve

- Horsepower to suit higher density materials

- Explosion-proof motors

- Controls such as variable frequency drives, motor starters and operator stations are available

- Spray nozzles for liquid introduction

- Jacket for heating or cooling

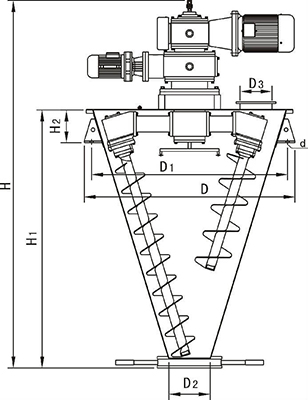

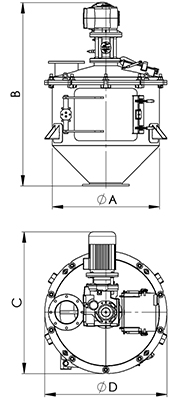

Vertical Ribbon Mixer , Nauta Mixer For Dry Powder , Vertical ribbon mixer machine barrel two asymmetric spiral rotation of the material up to lift, slow arm swing movement; the spiral outside the material, varying degrees into the stud, so as to achieve the full range of materials continue to update the proliferation, The two pieces of material mentioned in the upper part are converged to the central pits to form a downward flow of material, complementing the bottom vacancy, resulting in a triple mixing effect of the convective circulation; the standard conical screw mixer has two agitators Helix, the actual application according to the size of the equipment can be used single (a long spiral), double (the length of each one or two asymmetric spiral), three (two short and one long symmetrical arrangement) root screw; theoretically, Mixing the effect of the better; equipment generally use plum-shaped "dislocation valve", the valve and the bottom of the long spiral fit closely to effectively reduce the mixed dead angle, the drive in the form of manual and pneumatic optional; according to user needs, can also be installed butterfly valve , side valve discharge and so on.

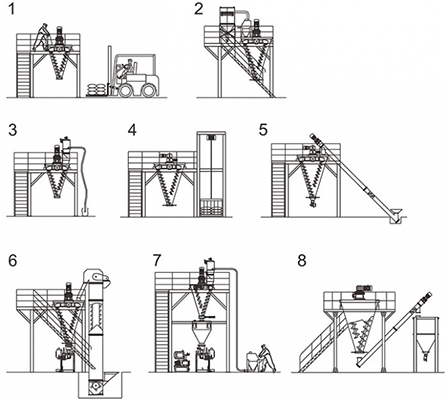

- conical mixer with manually feeding

- conical mixer, manually feeding device with dust collector

- conical mixer with vacuum feeder

- conical mixer with crane

- conical mixer with screw conveyor

- conical mixer with bucket elevator

- simple production line with conical mixer, vacuum feeder, storage tank and auto-packing machine.

- simple production line with conical mixer, manually feeding, screw conveyor to storage tank and auto-packing

ribbon mixer, ploughshear mixer, paddle mixer, conical mixer, continuous mixer, liquid mixer,all these mixers are custom-made according to different kinds of material

Ribbon blender machine with Powder Transfer systems , Working Plate form , Product collection BIN

Ribbon Blender with Vacuum powder transfer systems , Ribbon blender with working Plate form

Powder Blending plants in Pharmaceutical ,Protein Powder, food, Ribbon mixing plants in food, Ribbon mixers machine for medicines, horizontal mixers are widely used in chemical, medicine, food, and construction line. food material ribbon type mixing equipment line, flour blending and mixing , spice powder blending machine, seasoning blender machine with production line etc. Blender Machine with driven of motor, ribbon agitator mix the material quickly & clean and maintenances.

General Introduction

Ribbon mixer machine best suitable for chemical, Agro, Cosmetic , pharmaceuticals, food, construction line. mix powder with powder, powder with liquid, and powder with granule etc.

Ribbon blender machine with manual feeding, crane big bag feeding, screw conveyor feeding, vacuum feeding, bucket elevator etc. Mixing machine: double ribbon blender, single shaft mixer, mixing machine etc with Filling machine: storage silo, screw conveyor, packing machine, big bag etc.

Ribbon blender machine with system as dry ingredient bulk production blending line below:

- Ribbon blender machine with jumbo bag material and feeding the mixer

- Ribbon blender machine with mufti-level platform, manual undo the bag, mixing and packing with a bulk bag packer.

- simple mixer frame, feed the mixer manually with the help of a folk lift.

- using manual feeding platform, after mixing, screw conveyor send the material to the storage silo, a packer under it.

- load the material manually on the ground,use vacuum feed to transfer material into mixer, after mixing, pack with a bulk-bag packer.

- multi-stage vacuum feeder, store it after mixing, then packing.

- multi-level operation platform, elevator sending to material silo, mixing, storage, and then packing. Tower structure.

- bulket elevator feeding, mixing, storage, and packing.

- vacuum feeding, mixing, storage, packing.

- Manual feeding, mixing, storage, packing

Powder Ploughshear Mixer, Ploughshear Mixer, Putty Mixing Machine For Dry Ingredient

Applications of Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer for Fine Chemicals, Detergent, Pesticide, Colors

| Fine Chemicals | Fertilizer | Pesticide |

| Color Pigment/Dyestuff | Functional Compounds | Detergent |

| Battery Compounds | Catalyst Resin | Compounds |

| Stabilizer | Chemical Agents | Carbon Powder |

Powder of Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer :

| Vitamin | Ice Cream | Flour | Milk/WheyPowder |

| Enzymes | Starch | Flavorings/Spices | Bakery |

| Protein | Juice powder | Coffee |

Granules, Grains or Powder Containing Pieces Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Table Salt | Diet Foods | Grain | Convalescent Preparations |

| Tea Extracts | Fruit Drinks | Tobacco |

Fragile Materials Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Muesli | Instant Soups | Tea Mixes | Frozen Vegetable |

| Vegetable | Frozen Fruit |

Viscous Products Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Fruit Pulps | Chocolate | Wafer Filling | Cheese Spread |

| Baby Food | Cream |

Pharmaceutical Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Basic Pharma Materials | Active Agents | Pharma Intermediates |

| Tablets | Capsules | Pellets |

| Granules | Particles/Crystals | Moist Product |

Cosmetic product Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Titanium Dioxide | Talc Powder | Mica Flour |

| Kaolin Clay | Surface Active Agent | Disperse Agent |

| Coloring Powder | Mask Powder |

Applications of Life science and Healthcare product Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Infant Formula | Bacterial Cultures | Nutritional Supplements |

| Sports Nutrition | Aroma | Vitamin Compounds |

| Active Agent Mixes | Lecithin Powder | Mineral Substances |

Applications Chemicals / Agro / Fertilizeer / Detergent for Vertical Ribbon Mixer, Nauta Mixer For Dry Powder, Conical Ribbon Mixer

| Fine Chemicals | Fertilizer | Pesticide |

| Color Pigment/Dyestuff | Functional Compounds | Detergent |

| Battery Compounds | Catalyst Resin | Compounds |

| Stabilizer | Chemical Agents | Carbon Powder |

Intro:

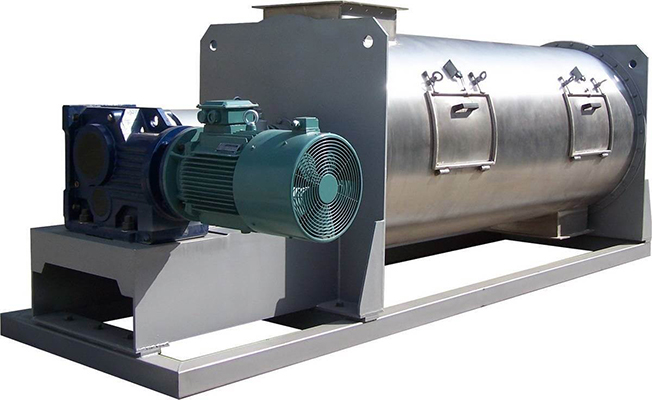

This mixer is broadly applied for the solid-solid (powder to powder) and solid-liquid (powder to liquid) and liquid-liquid (liquid to liquid) mixings in food, pharmacy, chemical industry, fertilizer, oil field, oil refining, animal remedy, coating, pigment, dyestuff and assistant, metallurgy, smelting, fireproof material, mine, building material, battery, electronic plastic,fodder, cultivation, biological project, health product, ceramic, glass, new material, nuclear material etc. trades. This mixer is greatly suited with mixed materials, will produce no lamination and maceration phenomenon to the mixing combined with thermo-sensitive materials and holds a good suitability to the mixing of rough materials, fine grains and extra-fine powders etc. various grains, fibers or lamellate materials.

Working principle:

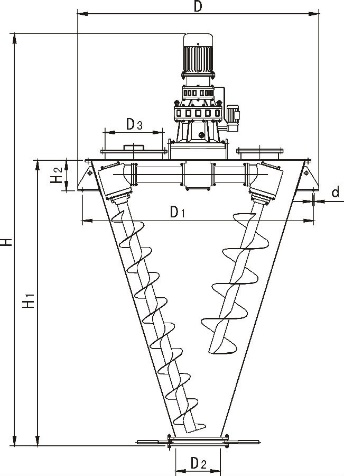

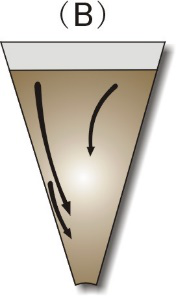

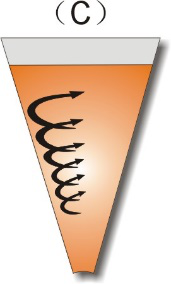

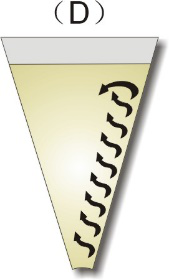

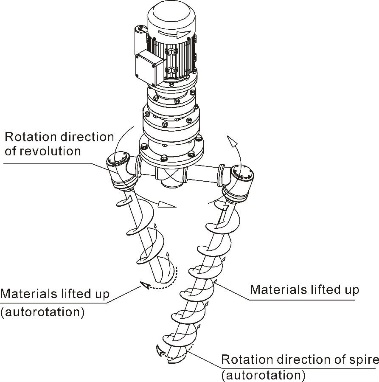

The quick autorotation and revolution of the two non-30.jpgsymmetric spires of the mixer makes the material lifted upward to form two non-symmetric spiral material streams from the lower to the upper along with the bucket wall (see Fig. A and B). The revolution movement of the spire driven by the rotating arm makes the material outside of the spire enter the stud envelope line in various degrees, some is mal-positioned lifted and some is thrown out of the stud so as to get the material on the full circumferential orientation continuously renewed and dispersed, the two material streams lifted to the upper are gathered towards the central countersink to form one downward material stream, supplementing the cavity on the bottom so as to form a contra-flow cycle (See Fig. A, B, C, D, ). Because of the compound of the above movements, the materials get quick evenly mixed and hold a higher mixing degree (see Fig. E, F).

Product introduction

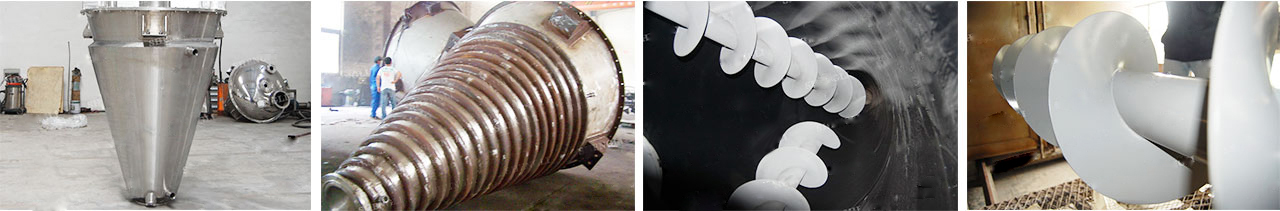

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; different material can also be used in parts, between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel can be sandblasting, wiredrawing, polishing, mirror polishing

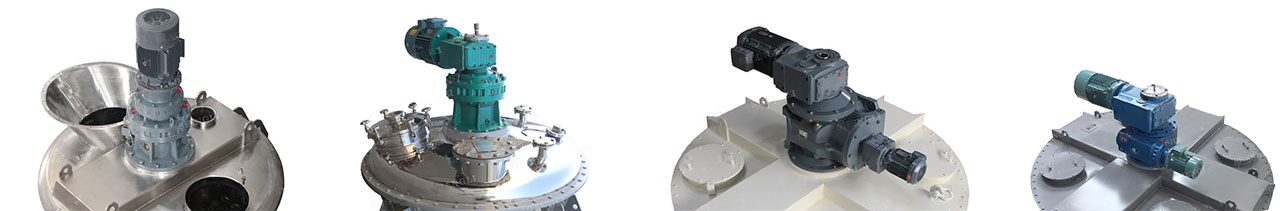

2.Reliable driven unit

The driven unit and power is varied according to different raw material, starting method, and processing.

Double screw conical mixer is equipped with appropriative double output reducer, which combines pinwheel, gear and warm and gear.

3.Excellent discharging unit

Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.The surface of the valve match the track of the bottom of screw, to reduce the mixing dead zone to the maximum, and to make the largest discharging area, so as to make sure no leftover. Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.Plum-blossom dislocation valve is easy to operate and control the discharging speed

4.Powerful auxiliary components

Equipped with circulation medium of jacket, the double screw conical mixer can realize the temperature control in mixing process.

In the mixer barrel, the part contact with material can coat some antiriot, anti-caking and metal isolation material according to different ingredient. In some severe wear conditions, the screw surface can be overlaid by some wear proof alloy.

If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

A、Mixing Effect

The standard double screws cone-shape mixer is equipped with two agitating augers, yet single(a long auger), double(two dissymmetrical augers with different length) or triple(three symmetrical screws with two long and one short) augers is adopted in fact according to the size of the device; theoretically, more angle augers there are, better the mixing effect is.

B、Cooling and heating

Cool or heat the materials through feeding the cold or hot medium into the jacket which is added to the outside of the cylinder of the mixer. Pump industrial water for cooling and steam or heat oil heated by electricity for heating.

C、Liquid-adding mixing

The mix of injecting liquid can be achieved by connecting the atomized spray nozzle with spray pipe which is inserted in the intermediate axle location of the mixer. With choosing the specific materials, the mix of powder and liquid can be conducted by injecting acid or alkali liquid.

D、Compression Resistance

The cover of the cylinder can be made as the shape of a dome, deceasing residue to clean easily while improving compressive strength of the mixer cylinder, which should be frequently used when pressure resistance cylinder is needed.

E、Negative Pressure Feeding

The cylinder of the mixer can be made as negative pressure chamber in specific process, which breathes the dry material with good fluidity in mixing chamber for mixing using soft pipe, without residue and pollution in the feeding segment.

F、Discharging Mode

The standard device typically uses plum flower-shaped “dislocation valve” that joints closely with the bottom of long screw to decrease mix dead angle effectively with two driving methods, manual and pneumatic. It can also use butterfly valve, ball valve, star-shape material discharging device, side discharge and so on according to the user’s requirements.

Specification

Standard Features:

- Volume: 10-20000L

- Stainless Steel or Carbon Steel

- Screw agitator for center discharge

- Designed for normal temperature and normal atmospheric pressure

- Feed Nozzle

- Dust Nozzle

- Manually operated or Pneumatic operated dislocated valve

- Packing Seal

- Safety limit switch on man hole

Optional Features:

- Carbon Steel, Stainless Steel 304, Stainless Steel 316L

- Internal pressure

- Sanitary type construction

- Dislocated valve, butterfly valve, slide gate valve, ball valve

- Horsepower to suit higher density materials

- Explosion-proof motors

- Controls such as variable frequency drives, motor starters and operator stations are available

- Spray nozzles for liquid introduction

- Jacket for heating or cooling