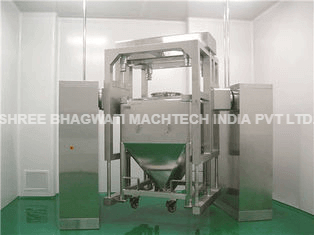

Bin Blender

APPLICATION:

Shree Bhagwati is No 1. In Pharma Equipments, we have 2000+ Satisfied Clients and we proudly providing a Wide Range of products and Bin blenders or Container tumblers are predominantly used for combination of dry powder for tablet assemble and capsule, which make easy to enhanced to add the tablets and capsules. This is a stopped up forced, totally stain free solitary step for convey structure. It can be grip more than one size of container tumblers.

Superior quality of granulation area the dry grain go from side to side to the IBC container for blending from side to side a stain free connection and the same IBC container is loaded over to the blender for combination. The IBC bin locked in the inactive frame in 15° then raise by hydraulic system in 15° disposed position after that the IBC bin revolve for combination with 3 aspect actions. This same container after coming together with loaded over the tablet press for unloading in to the tablet press hoppers.

Salient Features:

- This mechanism is Designed by cGMP – Current Good Manufacturing Practices compliance

- All contact parts are completed by SS 316.

- IBC Bin Blender for perfect dry mixer for lubrication of granules and homogenization mixing and conveying of the stuff to more preparation.

- Obtainable Capacity for 25 kg to 10,000 kg batch size and Custom Design Available.

- Interchangeable unrelated capacity of IBC Bin can be used on same machine use for mixing.

- This is a bunged up and enclosed structure where by a single step transmit material from Container of the bin blender is transfer to the tablet press hopper.

- In granulation area the dry granules enter to the container for merger through a dust free connection and the same container is loaded over to the blender for blending

- Totally stain free.

- Also an additional advantage is flexibility of this structure to switch more than one size of bunkers or containers so dispensation of dissimilar sizes of production batches in single equipment.

- Covered inflexible drive with attenuation mechanism box and motor in the machine structure.

- Hydraulic power pack structure for lifting of product bin for mixing.

- A appropriate reel around the cage with one entry point for the bin on removable trolley

- The charging hole with cover is provide on top with rapid opening and closing planning with dust proof joint for particle free transmit.

- IBC Bin having exonerated with butterfly control device and trolley for effortless mobility.

- Electric controls panel with cycle time

Optional Features :

- Charging Option:

- Product materials Loading & Unloading by Product container with trolley.

- Products Vacuum conveying transfer system.

- IPC / Bin loading.

- Exchangeable Product Container

- AC Frequency changeable drive for product container.

- Variable speed for product container by VFD.

- Optionally PLC Controls with HMI touch screen,

- Flame-proof motor and Push Button station.

- Optionally - Inline milling and loading with vacuum powder transfer systems.

- Powder Vacuum loading facility for material charging.

- Dust free closed system in Bin charging

- Option of 21cfr part 11 compliance control system

- Slow speed Blender with Gentle blending of Dry granules and powder

- Zero Jerk Load as machine is both dynamic and statically balanced

- Pneumatically actuated valves for dust free transfers

- Bins with Level sensory for automatic cut off

- Mechanical Seals on shafts for Pneumatic connections

- Validation Document – DQ , IQ , PQ , OQ and manual provide on additional extra cost.

We at Shree Bhagwati is Manufacturing for powder processing industries specially designing as per WHO, GMP, USFDA (U.S. Food and Drug Administration ), MHRA – (Medicines and Healthcare products Regulatory Agency ) , TGA (Therapeutic Goods Administration ) and GMP norms and requirements., specialized in Mixers, Blenders and Dryers mainly for Pharmaceuticals, API, Bulk Drugs & Intermediates, Food Processing, Cosmetics and Chemical process industries, Pharmaceutical Formulation and Bulk drugs ,Eg. Sustain Release, Enteric Release Coating on tablets , Organic and Inorganic chemicals , Agrochemicals and fertilizers , Nutraceuticals’ and Biotech Products, Speciality chemicals , R & D Institutes and colleges etc.

Bin Blender - IBC Bin / Cage/ Conta Blender - blending of liquids, powders and granules for Biotech, Chemicals, Cosmetics, Food, Nutraceuticals, Pharmaceuticals for United States, Canada and Puerto Rico , UK , Brazil , INDIA , Bangladesh , Russia etc demanded to transfer product formula to contract manufacturing company quickly.

Conta Blender

Developed by Shree Bhagwati’s Design Team, the Conta Blender represents a major advance that enables dust free transfer of powders and granules from Drying to Compression / Filling equipment’s with reduced material handling. The unique design ensures rotation in a diagonal axis and in an eccentric plane resulting in a homogeneous blend within a short time. It finds varied applications across multiple industries.

Features

- Designed for dust free blending and transfer of powders and granules.

- 0o stopping for easy docking and undocking of the bin

- Fencing around the cage with an entry point for the bin on detachable trolley

- Limit switch on entry door to prevent accidental operation of the cage

- Flexibility of accepting variable bin sizes providing wide range of batch volumes

- cGMP construction with cladded polished S. S. Sheets

- Containers of Varying size for varying batch size

- Built-in Butterfly valve (150 mm dia) at the bottom for discharge

- Suitable leak proof vent on top

Benefits For You

- Single step transfer from Drying to Compression / Filling equipments

- Superior mixing efficiency

- Reduced material handling

- Highly effective for low volume active blending with as low as 1% active

- Processing of different sizes of production batches with scale up data

- Dust-free operation

- No risk of segregation on extended processing

- No Cleaning down time as the product container is mobile.

Conta Blender used in Industries.

- Pharmaceutical

- Nutraceutical

- Food

- Chemical

- Cosmetics

General Description:

- cGMP construction with cladded polished S. S. Sheets with S.S 316 Contact parts and 304 Non-Contact parts

- Designed for dust free blending and transfer of powders and granules

- Home position docking and undocking of the bin

- Guard around the cage with an entry point for the bin on detachable trolley

- Limit switch on entry door to prevent accidental operation of the cage

- cGMP construction with cladded polished S. S. Sheets

- Containers of Varying size for varying batch size

- Built-in Butterfly valve (150 mm dia) at the bottom for discharge

- Suitable leak proof vent on top

Blender

CONTA – BLENDER

Conta Blender is a latest GMP concept of the dust free transfer of powders & granules at different stages from sizing/dispensing to compression filling of Tablets and Capsules. The process involves collecting the sized granules in container, wheeling it to the Blender, engage the same with clamping system, lift and tumble for the pre validated time in set nos. of rotations. Conta Blender has a flexibility of Batch Volume. It shuffles the product intimately resulting in homogeneous blend within 5-20 minutes.

SAILENT FEATURES

- • A/C Drive is provided to take care of starting Torque.

- • 0° stopping for easy docking and undocking of the bin.

- • A suitable fencing around the cage with an entry point for the bin on detachable trolley.

- • Limit switch on entry door to prevent the accidental operation of the cage.

- • Variable bin sizes.

- • Capacity Available: 5 Kgs. to 1000 Kgs.

Optional Features:

- Flexibility of accepting variable bin sizes providing wide range of batch volumes

- CE Certified

- Option of 21cfr part 11 compliance control system

Specification:

| MODEL | GROSS WORKING CAPACITY (LIT) | WORKING CAPACITY (LIT) | LENGTH (MM) | BREADTH (MM) | WIDTH (MM) | MOTOR (H.P) | WEIGHT (KG) |

|---|---|---|---|---|---|---|---|

| SCB LAB | 1-30 | 0.7-21 | – | – | – | 1 | – |

| SCB75 | 75 | 53 | 1000 | 2000 | 1500 | 2 | 700 |

| SCB150 | 100 | 70 | 1800 | 2000 | 1500 | 3 | 800 |

| SCB300 | 300 | 210 | 1800 | 2800 | 2000 | 3 | 1000 |

| SCB500 | 500 | 350 | 1800 | 3000 | 2200 | 5 | 1200 |

| SCB750 | 750 | 525 | 1800 | 3200 | 2200 | 5 | 1500 |

| SCB1000 | 1000 | 700 | 2000 | 3500 | 2400 | 10 | 1800 |

Contact us for more information to Manufacturing of UNITIPPER – Lifting & tipping device or to discuss your requirements. Email us at sales@bhagwatipharma.com / contact@bhagwatipharma.co.in

- Powder Mixing:Mix different kind of powder materials to required uniformity.

- Granule Mixing:

- Mix the granules with lubricant, binder or essence oil of flavor.

- Mix different kind of granules to required uniformity.

Application

Apply for mixing powder, granule, lubricant additive, binder, essence oil of flavor of Western medicine, Pharmaceutical, medicine and health food.

Feature

- Convenient and precise for cleaning.

- Mixing ratio up to 1 / 10,000.

- With safety railing and interlock device.

| We have great pleasure in introducing ourselves as a manufacturer of high quality machinery for Pharmaceutical Industry. We have been rendering service to pharmaceutical industries for the past two decades with our quality machines for high speed mixing and wet granulating of Pharmaceutical formulations of tablets and capsules, 100% inspection of vials and ampoules and labeling machine for ampoules and Vials and Material handling equipments. |

| We have full fledge factory spread on 27,000 sq. ft. at GIDC, Ankleshwar (Gujarat). We have with us more than 55 skilled workmen and 8 qualified engineers and technicians. A dedicated cell of service persons, is stationed at Ankleshwar and Ahmedabad to take care of commissioning and after sales service required for our esteemed customers. |