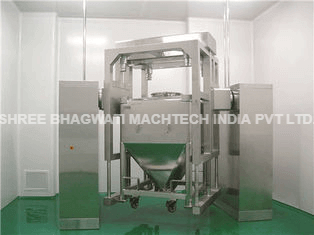

Cage Blender

APPLICATION:

SHREE BHAGWATI makes complete range of tumbler blenders or IBC Container tumblers are used predominantly for amalgamation of dry powder for tablet fabricate and capsule, which bring about improved dispense for medication and pill. This is a bunged restricted, completely dust free retiring step put out structure. It can be handling further than one size of IBC container tumblers.

Latest Design of granulation area the dry granules go from beginning to end to the IBC container for amalgamation from beginning to end a dust free association and the same IBC container is loaded in overindulgence of the blender for amalgamation. The IBC bin locked in the motionless frame in 15° after that lifted by hydraulic formation to mounting for moving altitude subsequent that the IBC bin turn around for amalgamation. These indistinguishable IBC containers after amalgamation rise above the tablet press for unloading in to the tablet press hoppers.

SALIENT FEATURES:

- We have the Latest Infrastructure of cGMP - Current Good Manufacturing Practices compliance

- All contact parts would be SS 316 and non contact parts would be SS 304.

- IBC Bin Tumbler Blender for Premium quality for dry beater for lubrication of granules and homogenization amalgamation and diffusion of the material to more development.

- Indistinguishable distorted ability of IBC Bin can be used on same method use for integration.

- This is a stopped up and protected preparation where by a retiring step put out the material from storage place of the Conta blender is transport to the tablet press hopper.

- In granulation area the dry granules go from beginning to end to the storage place for amalgamation during a dust free bond and the same storage place is loaded over to the blender for combination

- Totally dust free.

- Also an additional Advanced Technology is flexibility of this structure to handle more than one size of bunkers or containers so allowance of changed sizes of manufacture batches in single paraphernalia.

- Covered inflexible drive with reduction machinery box and motor in the mechanism pillar understanding.

- Hydraulic power pack conformity for lifting of product bin for amalgamation.

- A proper reeling roughly the cage with one entrance point for the bin on detachable trolley

- The charging hole with cover is provided on top with quick opening and closing preparation with dust proof joints for particle free transmit.

- IBC Bin having exonerated with butterfly control device and trolley for trouble-free mobility.

- motivating controls panel with cycle time

Optional Features :

- Charging Option:

- Product materials Loading & Unloading by Product container with trolley.

- Products Vacuum conveying transfer system.

- IPC / Bin loading.

- Variable speed for product container by VFD.

- Transaction able product container.

- AC Frequency changeable drive for product container.

- Optionally PLC Controls with HMI touch screen,

- Flame-proof motor and Push Button station.

- Optionally - Inline milling and loading with vacuum powder transfer systems.

- Powder Vacuum loading facility for material charging.

- Dust free closed system in Bin charging

- Option of 21cfr part 11 compliance control system

- Slow speed Blender with Gentle blending of Dry granules and powder

- Zero Jerk Load as machine is both dynamic and statically balanced

- Pneumatically actuated valves for dust free transfers

- Bins with Level sensory for automatic cut off

- Mechanical Seals on shafts for Pneumatic connections

- Validation Document – DQ , IQ , PQ , OQ and manual provide on additional extra cost.

We at Shree Bhagwati is Manufacturing for powder processing industries specially designing as per WHO, GMP, USFDA (U.S. Food and Drug Administration ), MHRA – (Medicines and Healthcare products Regulatory Agency ) , TGA (Therapeutic Goods Administration ) and GMP norms and requirements., specialized in Mixers, Blenders and Dryers mainly for Pharmaceuticals, API, Bulk Drugs & Intermediates, Food Processing, Cosmetics and Chemical process industries, Pharmaceutical Formulation and Bulk drugs ,Eg. Sustain Release, Enteric Release Coating on tablets , Organic and Inorganic chemicals , Agrochemicals and fertilizers , Nutraceuticals’ and Biotech Products, Speciality chemicals , R & D Institutes and colleges etc.

SPECIAL THINGS ABOUT SHREE BHAGWATI:

- We are giving the World Wide Installations

- Custom Design Available as per the customer request.

- Satisfaction Guaranteed for Prompt Technical Support.

- Fast Delivery for anywhere

- Powder Mixing Mix different kind of powder materials to required uniformity.

- Granule Mixing:

- Mix the granules with lubricant, binder or essence oil of flavor.

- Mix different kind of granules to required uniformity.

Application

Apply for mixing powder, granule, lubricant additive, binder, essence oil of flavor of Western medicine, Pharmaceutical, medicine and health food.

Feature

- Convenient and precise for cleaning.

- Mixing ratio up to 1 / 10,000.

- With safety railing and interlock device.

- Designed for dust free blending and transfer of powders and granules

- 0o stopping for easy docking and undocking of the bin

- Fencing around the cage with an entry point for the bin on detachable trolley

- Limit switch on entry door to prevent accidental operation of the cage

- Flexibility of accepting variable bin sizes providing wide range of batch volumes

- cGMP construction with cladded polished S. S. Sheets

- Containers of Varying size for varying batch size

- Built-in Butterfly valve (150 mm dia) at the bottom for discharge

- Suitable leak proof vent on top

- Single step transfer from Drying to Compression / Filling equipments

- Superior mixing efficiency

- Reduced material handling

- Highly effective for low volume active blending with as low as 1% active

- Processing of different sizes of production batches with scale up data

- Dust-free operation

- No risk of segregation on extended processing

- No Cleaning down time as the product container is mobile

- Pharmaceutical

- Nutraceutical

- Food

- Chemical

- Cosmetics