Ploughshare Mixers are perfect for admixture powders and granules and canbe used for light-weight paste-like or cream substances. The mixer is based on an examined intermixture creation that has a double admixture movement making certain short and competitively priced blending.

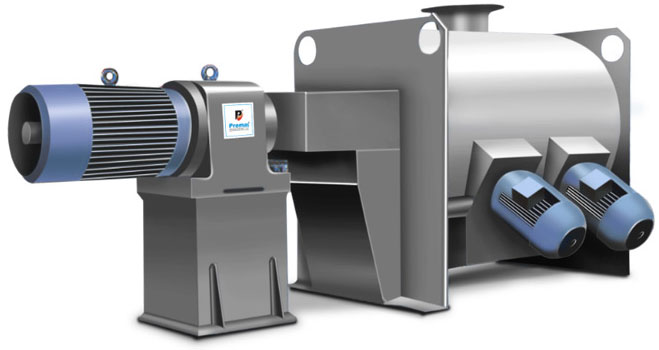

This is a horizontal mixer including a horizontal, cylindrical instrumentality enclosure plough shaped admixture components hooked up on a horizontal shaft.

The blending result is extended with the aid of using separately driven, excessive-velocity rotating choppers or a couple of choppers, that during cooperation with the plough shape admixture additives, disperse the lumps and agglomerations or pasty components with the powdery carriers.

These Mixers are provided with liquid feeding devices, jackets for heating/cooling, choice of seals, vacuum suitableness for drying, and sundry materials of creation (like mild-steel, stainless-steel, Hastelloy, Monel) to match the approach substances. The Mixer is moreover given a solvent recuperation system.

Standard features of plowshare Mixer

- Capacity stages from 100-30000L

- Mild Steel/Stainless Steel creation

- One end welded and one end latched

- Normal Temperature and Pressure in the mixer

- Gear Reducer Motor

- Gland Packing Seal + Air Purge Seal

- Pneumatic Operated Outlet Valve

Plough Shear Mixer is meant for massive responsibility blending of every Dry and Wet material. (Also named plowshare mixer, plow mixer, plough mixer) includes a cylindrical drum containing plough-shaped admixture components which might be hooked up on a horizontal shaft. It creates a mechanical fluidized mattress admixture movement.

Plough shear mixer is hugely applied withinside the combination of chemical substances, pigment, scientific distinctiveness substances, and feedstuff, especially in the combination of fragile stable grain; in a completely quick time, the mixer has clever excellent blending for the substances that include a pleasant difference in grain and density.

The plough shear mixer is designed to preserve monetary tactics like admixture, Drying, Reacting, Moistening/Coating, Sterilization, Granulation, and Emulsification.

Plough shape shovels hooked up on an important shaft with their intendeds are penetrable via the dense powder mass at some point of a cylindrical drum or a vessel.

The batch plough shear mixer is the maximum flexible mixer type supplied with an in-intensity type of applications:

- Dry powder commixture

- Paste admixture

- Mixing of moist slurries

- Wet granulation

- Liquid coating of powders and granules

- Fat and oil incorporation

- Vacuum drying

Mixer shaft in a horizontal, cylindrical drum. The size, variety and positioning, geometric shape, and peripheral velocity of the mixing. Plough Shear Mixer Shuffling of the combination is performed with the aid of using the wider end of the shovels.

Penetration observed with the aid of using the agitation of the mass in a quick succession of the specifically designed blades ends in the homogeneity of powder mass every in dry and moist stages. Applicable dough formation is reached in a later approach.

A centrally hooked up chopper will then perform to get moist granules of uniform size. The combined equal mass is discharged from the lowest of the mixing drum that is provided with a flush-match discharge port.

One of the advantages of the plowshare mixer is that those admixture instances range little or no among the various gadget sizes. The mixer is fed from on top. In smaller, mainly manually operated mixers, this includes an outsized guide to get entry to purpose. In the case of gadget-managed manufacturing systems, the uncooked substances come again from upstream silos, scales, or comparable dosing instrumentation and arrive in the mixer thru one or many pipes. The mixer is discharged from the rock backside of the drum.

Advantages:

- Highest high-satisfactory mixes in quick commixture instances

- Gentle remedy of the merchandise

- Reliable reproducibility of the combination of high-satisfactory

- Combined tactics in a single unmarried gadget

- Maximum convenience

- Low upkeep style

- Easy accessibility to any or all inside additives of the mixer

Ploughshare Mixer marketplace is cut up with the aid of using type and with the aid of using Application. For the quantity, 2017-2028, the growth amongst segments gives accurate calculations and forecasts for income with the aid of using kind and with the aid of using Application in phrases of quantity and well worth.

This evaluation will let you amplify your commercial enterprise with the aid of using concentrating on the certified area of interest markets.

Plough Share Mixer Applications

- Adhesives/putties

- Agrochemicals

- Animal feed

- Biscuit creams/dough

- Blending

- Break lining and industrial gaskets

- Car body fillers/putties

- Cements

- Ceramics

- Chemicals

- Confectionery products

- Confectionery rework

- Cosmetics

- Detergents

- Dough

- Drying

- Dyes and intermediates

- Fertilizers/Insecticides

- Fiber glass resin dough's Putty

- Filter cake re-slurring

- Fire extinguishing powder

- Food flavouring/additives

- Foodstuffs

- General

- Glass industries

- Granulated rubber premixes drying and granulations

- Heavy plastic masses

- Homogenizing

- Minerals

- Multiple phase reactions

- Paints

- Pesticides

- Pharmaceuticals

- Powdered rubber

- putties and marzipan

- PVC pastes

- Refractories powder coatings

- Slurries

- Sponge/cake mixes

- Sugar/marzipan paste

- Tile adhesives/grouts

- Toiletry pastes

- Veterinary

- Waste treatment

Plough share mixers, plow mixer & Dryer, plough mixer for Foods , Starch , Flavoring , Coffee , Chocolate , Nutraceuticals , Cosmetic , Pharmaceuticals

Ploughshare batch mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer

Plough shear mixer is a single shaft compulsory mixing equipment. Several pieces of plough shears are installed on the main shaft in dislocation and continuously, which avoid the mixing dead zone in structure. When operating, material in mixer tank move following the direction of the continuous vortex centrifugal force generated by the continuously blending plough shears, thus, to achieve scattering, dispersing and fast mixing of material.

Plough mixer is widely used to mix powder, granule, and small liquid additives in food, chemical, and construction line.

It is particularly good at handling food additives, mortar, fertilizing, sludge, plastic, and special building material. The powerful shearing effect makes it high efficiency, and good mixing result.

Technical parameter:

Batch working volume: 0.1-20cbm

Batch weight: 0.3-15tons

Material: 316L, 304, mild steel

Mixer is equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket, sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on. Different heat medium requires different jacket, it can be used for heating and cooling, while the temperature should be within 250 Celsius degrees. If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

Feed characteristics:

Special sticky and clumped powders, Fibrous powders

Applications of Manufacturer of Ploughshare Batch Mixer, Ploughshare Mixer for Solids and Powders, Plowshare mixer, Plough mixer, Plough Shear Mixer, Plow Mixer models.

Pharmaceutical, herbal & alternative medicine, chemicals & fine chemicals, food, agriculture, cement & ceramics, cosmetics and detergents, paints & pigments

The mixer can be equipped with highly durable surfaces, high-strength structural steels, stainless steels and special materials.

Depending on the production volume and the application in hand, machine sizes between 130 litres for small batches and 30,000 litres for large production projects are available.

Smaller machines with capacities between 5 and 50 litres are also available for laboratory applications. Typical mixing times for dry recipes are about 1-3 min.

Benefits of our Ploughshare Batch Mixer

– Shortest mixing time

– Batch repeatability

– Excellent particle distribution

– Maximum saving

– Guaranteed scale-up

Applications:

- Food Premix and Spice Blending

- Mixing of crude materials

- Mixing of Metal Powders and Bonding material

- Granulation

- Dry blend Mortar

- Homogenization of powder material in Pharmaceutical, Chemical, fine Chemical and so on.