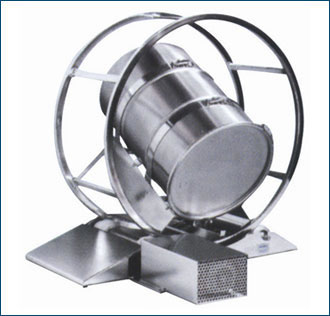

Drum/ Barrel mixer is fastening paraphernalia used in pharmaceutical and chemical industry. Drum blender are tremendously efficient combination paraphernalia used for combination of powder. These blenders have gallon drums which spin in order to mix powder. The combination events connect loading the material into the drum, which is restricted in a hoop and rotate consequently.

This Barrel blender is tremendously functional for mixing of ingredients or raw materials to be transmit in barrels. Different other blender, this mixer does not have any internal affecting parts like blade or impellers; so the blender avoid deterioration of the matter from friction-induced heating, known with the intention of the drum has no deceased space, so the substance is time after time blended. The drum mixer is powered by pneumatic or motivating motors and available in a diversity of sizes. These mixers are configured in such a move in the direction of so that suitable amalgamation and superiority control of the end product is attained.

The unique Mixing blades are fully welded to the rotating drum and completely fluidise the mixture with every revolution; the combination of low speed and no affecting parts inside the mixer produce a no shear, moderate mixing accomplishment. Surrounded by the fluidised combination powders and granule of extensively dissimilar bulk density and constituent part size can move generously ensure a quick and well-organized mix

Obtainable in 14 criterion batch sizes from 50L to 25,000L, enduring, lab size and non-standard version are also shaped to match your obligation. A wide mixture of opportunity are obtainable, we will intend your manufacturing mixer approximately the needs of your procedure. A reverse drum mixer (also usually called a non-tilting mixer) is a type of existing mixer that produces existing in solitary batch. The complete drum rotates approximately its alliance as resources are loaded from side to side a accuse chute at one end of the drum and exit from side to side a discharge chute at the conflicting end of the drum.

Drum blender intended for consistent mixing and combination application with pellet, granule and powder worn in a lot of huge scale plastics and petrochemical application for moderate batch blending uniformity. Covered turbine pieces allow for larger particles and pellets to flow without hindrance. This intend is the perfect volume mixer for fluoropolymers ,vinyl composite floor tile cubes , specialty compounds, agro chemical products, industrial detergents, plastic pellets, HDPE pellets, catalysts, plastic additives, granular and others.

The subsequent character makes the Rotary Drum Blender an extremely well-organized blender and easy to function.

- Moderate Mixing: The contra flow blades lift and rapidly relocate the fluidised creation approximately the blender; under these situation powder and granule of extensively dissimilar bulk density and subdivision dimension can move generously ensure a quick and moderate mix.

- Low power: Low rotating drum speed and the least quantity number of addition blades shared with no moving part in the mixer formation near idyllic situation to softly mix flake or highly abrasive products with minimum wear. This also provides for low maintenance and operating costs.

- Total discharge: All the fluidised filling are discharge via the combined inlet and outlet this also provide low headroom inline filling and empty via the straightforward flap valve and single revolving seal.

- Protection and simple to clean: The completely covered combination drum is with no trouble inspect or clean via an outsized right of entry door fixed with a code key interlock.

- Consignment or permanent sizes ranging from laboratory to outsized mass manufacture units.

- Disinfected design of all combination blades, inlet / outlet chutes and interior surfaces get rid of any corner for substance to stick to.

- Low Costs The well-organized mixing blade intend combine with no impel parts or bearings being uncovered to the product results in smallest amount power needs and preservation free function for extended period of incessant operation.

- The machine is intended by cGMP – Current Good Manufacturing Practices compliance.

- All contact parts would be SS 316 & non contact parts would be SS 304.

- Accessible capability is 50kg and 25,000 kg.

- This is a congested and incomplete arrangement for merger and store.

- Most important advantage of this arrangement is that it is totally dust free.

- Control panel with rotation regulator.

- substitute for variable speed