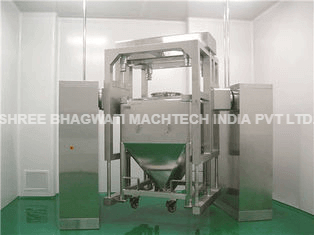

Bin blender is one of the ideal examples of consignment blending anywhere sized granules together in a container, dock to the blender arm, clamped, and lifted from a solitary end and fall for the pre-validated instance. The minute cut off blending action prevents superfluous fines or changes to subdivision shape or size. Short cycle time Fast loading, complete release, low powder obligation and smallest amount preservation are some of the quality. Conta blending improves competence compare to conservative blender since of combination in the oblique and unusual plane. Huge flexibility – dissimilar ability of bins (for e.g. 200 Ltrs., 400 Ltrs., 600 Ltrs.) can be dock in the solitary fork of the same bin mixer. Also a variety of shapes of bin can be accommodating. (For eg: You could dock an Octagonal or twin Blender body in the same arm of the Conta bin). The arm of the bin blender does not have any nylon roller or pins. It is a straightforward sliding arrangement with a fix in place arrangement for resting. Bin Blender with Vertical hydraulic clamping type.

As regard to its clamp, it happens with the help of three hydraulic cylinders which is a fraction of the combination arm. In case of heavy bins, (single column amalgamation) it is in an ideal world used chiefly for 1500 Ltrs to 3000 Ltrs capacity. The blender bin will have to be reserved at the point of clamp. There is no management of the blender bin into the amalgamation arm in this container. All suitable safety method is measured. There is a pressure switch in the circuit such that in case of any hydraulic leak, the major drive motor stops right away bring the machine to a stop the progress. These are characteristically conventional Bin Blenders with the only dissimilarity form the way it is being clamped.

In these kinds of blenders, the Blending bin has got two cavity lugs on every side of the body. The amalgamation arm has got a junction with split type openings at every end. As soon as the bin is inserting into the limb and the two forks enter the lugs in that order, following complete introduction the end of the fork opens like a flower thereby completely locking the bin from getting out the arm throughout blending function. The opening of the tear end of the arm happens through a hydraulic cylinder (50mm stoke). The split end is connected by a tensile spring.

To make sure the spit arm does not collapse throughout amalgamation there is a hydraulic pressure switches obtainable which stop the major motor in case the pressure drops next to the set pressure. A pneumatic also as a supplementary safety limit switch in provide for the conclusion of the stroke. In case the 50mm stroke is unfinished, the main drive motor would not begin.

In extra to all the compensation of a conservative bin blender, there is a little more to add:

- Hydraulic Locking of the bin with criticism to the PLC ensure that there is no physical interference whatever.

- The parallel cavity preparation is worn for the amalgamation series as well as the copying of the bins on top of the compression machines.

- Very simple and hassle free arrangement ensure compression of the complete mechanism. in an ideal world suited from 500 Ltrs to 1500 Ltrs

An additional pattern of batch amalgamation, alike to the conta blender excluding that in its place of a solitary point lifting, the bin is lifted at two ends and rotated. Consequently blending occurs only in a slanting plane and not in unconventional plane.

- Suppleness of combination varying volumetric capacity is achieved in these blenders.

- following amalgamation, the subsequent option are obtainable

- Release the blended inside into containers of varying heights.

- In case of great volume, the blended bins itself can be wheeled to the wanted position of release.

SPECIAL THINGS ABOUT SHREE BHAGWATI:

- We are giving the World Wide Installations

- Satisfaction Guaranteed for Prompt Technical Support.

- Fast Delivery for anywhere

Bin Blender, IBC Blender, Pharmaceutical Blender

Pharmaceutical Single column Lifting Bin Mixer Blender – Bin Mixer Blender, Pharmaceutical Mixer Blender, Industrial Bin Mixer Blender , It can automatically complete all actions of the mixing hopper including clamping, lifting, mixing and lowering. It is mainly composed of single column, lifting system, rotary system, electric control system and pharma bin, etc.

Push the bin container into the rotary arm and lock the nut. Start the control system and lift the bin to the mixing height. The control system will carry out automatic mixing according to the set time, rotation speed and other set parameters. After the mixing operation is finished, it is positioned at the horizontal position. The bin will automatically lower to the ground, the equipment will stop and process data will be printed. Loosen the locknut of the rotary arm, and push the bin out and transfer it to the next process procedure.

Shree Bhagwati Make different model Bin Blender , IBC Bin Blender & Bin Blending Machine ,Bin Blender Machine , Pharmaceutical Ibc Blender.

Shree Bhagwati Make different model Bin Blender , IBC Bin Blender & Bin Blending Machine ,Bin Blender Machine , Pharmaceutical Ibc Blender.

Bin Blender is mainly used in the solid dosage production for mixing granules with powder, granules with granules, powder with powder. It is ideal mixing equipment for pharmaceutical factories, meanwhile Shree Bhagwati range ibc blending system also used in food, health food, chemical and cosmetics industries. Shree Bhagwati IBC blending system structural performance has reached the level of similar international products.

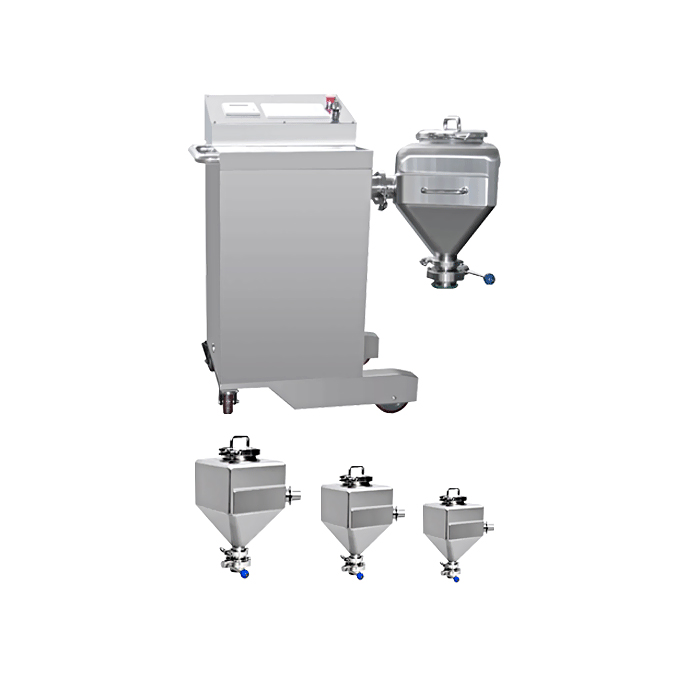

Lab Blender, Bin Blender , Laboratory Bin Blender , Lab Bin Blenders , Lab bin blender machine from Shree Bhagwati

Laboratory Bin Blender

- Easy operation, maintain and clean

- Small space and low power consumption

- Data recordable and printable with mini printer

- Intelligent PLC control and HMI

- Different size pharma bins are interchangeable

Shree Bhagwati Series Laboratory Bin Blender also named Lab Bin Blenders. The blending bin can realize fast replacement of bins, different volumes and shapes according to your different varieties of materials process requirements. It is mainly used for the test of blending different components of dry powders with dry powders, granules with granules, or powders with granules in laboratories. It is an ideal equipment for exploring the best process parameters in material blending, and a mechanically and electrically integrated advanced experimental machine. Shree Bhagwati Process Equipment Series Laboratory Bin Blender is widely used in the solid dosage production, in pharmaceutical laboratory, university laboratory, also used in chemical, food, health food industries.

Shree Bhagwati Pharma Machinery Company Series Laboratory Bin Blender is a highly efficient equipment unique design specifically for R&D and laboratory. The lab bin blenders adopt the most advanced design, featured by reasponable structure, stable performance and simple operation. With reasonable design and convenient operation, the equipment can be totally installed on a moveable trolley.

Shree Bhagwati Series laboratory bin blender is made of stainless steel, inner and outer surface of the bin is smooth without dead angle and exposed screws, blending in a sealed space to avoid dust and cross contamination. It fully meets FDA/cGMP compliant requirements.

Intelligent PLC control system and HMI to guarantee consistency and accuracy, homogenous blending of dry powders and granules, powders and powders, or granules and granules. Shree Bhagwati laboratory blenders are easy to use for all material blending processes.